Social

Dongwon Metal is committed to creating a safe and healthy workplace environment for all stakeholders. This commitment is embedded in our activities, products, and services. Moving forward, we will prioritize the health and safety of our employees and partners as our foremost value, fulfilling our responsibilities as conscientious members of society. We will continue to refine and strengthen our health and safety management policies

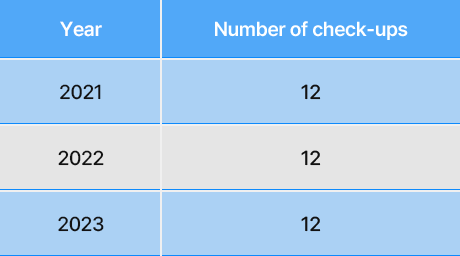

Dongwon Metal has established the Occupational Health and Safety Committee to hold quarterly meetings to discuss and establish improvement measures for safety-related issues such as accidents, revision of health and safety management regulations, and employee health improvement. In addition, the company sets annual health and safety goals and conducts thorough analyses of accident causes, along with comprehensive training, to prevent accidents from recurring.

In 2023, Dongwon Metal established a health and safety management policy aimed at preventing potential disasters across its operations, including the entire supply chain, establishments, distribution network, and sales channels, to provide a safe and healthy working environment and safeguard the value of life.

This policy is rooted in domestic and international health and safety laws, regulations, standards, and guidelines, such as ISO 45001. It reflects the company's health and safety management policy and its strategies and objectives for promoting health and safety management.

The policy, applicable to all domestic and international establishments, is recommended for adoption by stakeholders such as suppliers, partners, and distribution networks. Dongwon Metal actively promotes initiatives such as expanding safety inspections, fostering a safety-oriented culture, and integrating new safety technologies.

The company remains committed to ongoing improvement efforts across various business areas, including environmental, health, and safety management.

| Activity | Outlines |

|---|---|

| Risk Assessment | Identifying and preventing risks and hazards in the work environment, machinery, equipment, raw materials, gases, fire, and other harmful factors |

| Installation of Safety Signs | Attaching warning signs for hazardous locations, facilities, materials, and emergency response guidance at identifiable locations |

| Work Environment Safety Measures | Establishing standards for managing locations prone to falls, collapses, falling objects, natural disasters, and other potential hazards, and conducting regular maintenance checks |

| Machinery, Equipment, and facility Safety Measures | Implementing protective measures considering the functionality and characteristics of machinery, equipment, and facilities, and maintaining them to prevent potential hazards |

| Prevention of Health Hazards and Health Measures | Implementing necessary preventive and health measures to prevent health hazards caused by raw materials, gases, noise, etc. |

| Provision of Personal Protective Equipment | Mandating the use of appropriate personal protective equipment in the work environment and providing and managing PPE |

| Emergency Response Training | Conducting ongoing training based on emergency response scenarios for situations such ad falls, entrapment, electrocution, fire, explosion, and hazardous material leaks, and regularly checking the functionality of related equipment |

| Hazardous Material Management | Compiling and providing material safety data sheets for handled hazardous materials, and removing physical/chemical Hazards |

| Accident Investigation | Conducting investigations into accidents to determine their causes and devising measures to prevent recurrence. -Regularly analyzing occupational accident statistics and reflecting them in safety and health performance improvement goals |