Environment

Dongwon Metal has implemented an environmental management system overseen by the highest decision-making body, which monitors and governs environmental management according to company-wide environmental policies and regulations. Through environmental management, Dongwon Metal pursues sustainable growth, values people, and takes social responsibility.

ESG Committee

Climate Change Response Council

Project Office

Steering Committee

Domestic establishments

Overseas corporations

Group ESG TFT

[Composition of DONGWON Metal Environmental Management Policy]

1. Compliance with environmental regulations 2. Operation of the environmental management system 3. Business-related environmental impact management 4. Pollution prevention and environment protection 5. Transparency in the environmental managementAt Dongwon Metal, we are increasing financial support and investment in research and development for auto parts of HEV and EV to reduce greenhouse gas emissions.

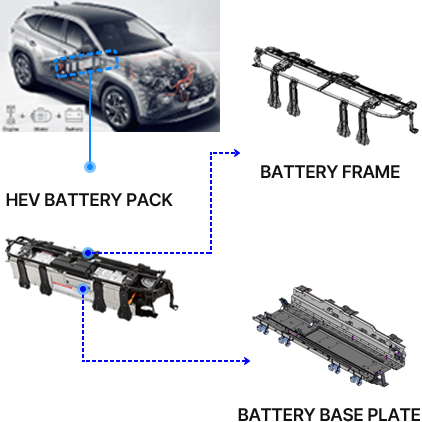

BATTERY FRAME for HEV

'Utilizing high-strength pipes produced by Dongwon Pipe, we engineer them to possess an optimal rigidity structure, maximizing the safety of eco-friendly vehicles.| Part Name | Illustration | Applicable Vehicle Models/Construction Method |

|---|---|---|

|

BATTERY FRAME |

|

Applicable Vehicle Models SX2 HEV, CN7 HEVNX4 HEV, NQ5 HEV DN8 HEV, DL3 HEV GL3 HEV, GN7 HEV Construction Method Pipe bending, CO2 welding |

|

BATTERY |

Applicable Vehicle Models NX4e HEVConstruction Method Press/hardware assembly |

|

|

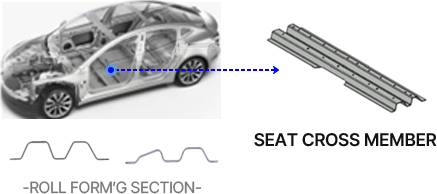

SEAT CROSS MEMBER |

|

Applicable Vehicle Models SX2 EV, SG2 EVConstruction Method Roll-Forming, Restrike |

BATTERY BASE PLATE for HEV

The battery baseplate for eco-friendly HEVs enhances safety by protecting the battery pack from vibrations and impacts.SEAT CROSS MEMBER for EV

One of our core construction methods is Roll-Forming, which allows for the mass production of high-quality productsBATTERY MODULE PLATE for EV

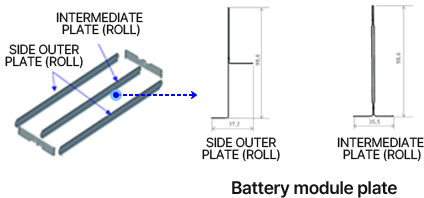

It serves as a framework for the EV battery module, supporting and protecting the battery cell. The Roll-Forming construction method is employed to reduce costs and facilitate the mass production of high-quality products.PACK SIDE MEMBER for EV

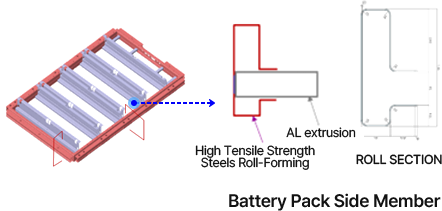

The application of the Roll-Forming technique achieves mass production, high quality, and cost reduction.| Part Name | Illustration | Applicable Vehicle Models/Construction Method |

|---|---|---|

|

BATTERY MODULE PLATE |

|

Applicable Vehicle Models Material: SUS290,Thickness: 0.8mm Construction Method Roll-Forming, Laser trimming,Powder coating |

|

BATTERY PACK SIDE MEMBER |

|

Applicable Vehicle Models Material: SGAFC 1470,Thickness: 1.0t Construction Method Roll-Forming, laser Piercing |

Aluminum Door Frame(DR FRAME)

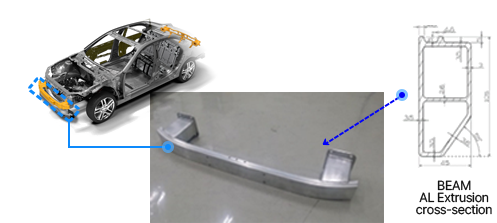

Compared to traditional steel doors, aluminum doors offer an approximately 31% weight reduction due to a decrease in the number of components and the use of low-density aluminum. This helps to reduce the vehicle's overall greenhouse gas emissions.Aluminum Bumper Beam(BUMPER BEAM)

Compared to traditional steel bumper beams, aluminum bumper beams offer an approximately 35% weight reduction due to the use of low-density aluminum and a decrease in the number of components. Additionally, they ensure collision safety performance with high-strength aluminum.Aluminum Door Impact Beam(DR IMPACT BEAM)

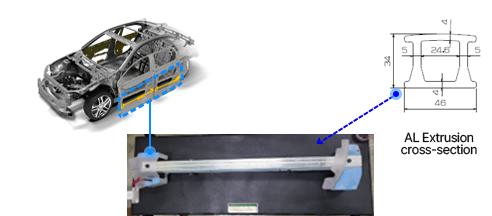

Compared to traditional steel beams, aluminum beams are approximately 30% lighter due to their lower density. By employing high-strength aluminum materials, we ensure both weight reduction and enhanced side-collision safety performance| Part Name | Illustration | Applicable Vehicle Models/Construction Method |

|---|---|---|

|

Aluminum Door Frame |

|

Applicable Vehicle Models Aluminum 6000 series extruded productConstruction Method Extrusion, roll bending, stretch bending |

|

Aluminum Bumper Beam |

|

Applicable Vehicle Models Aluminum 6000~7000 series extruded productConstruction Method Extrusion, stretch bending |

|

Aluminum Door Impact Beam |

|

Applicable Vehicle Models Aluminum 7000 series extruded productConstruction Method Extrusion, roll bending |